Hengshui Jrain Frp chemical products for frp applications a comprehensive guide

Sandvik, another industry giant, has a long history dating back to 1862. Their rock drilling solutions are synonymous with reliability and productivity. They offer a comprehensive range of products, from top hammer drills to down-the-hole hammers, designed to meet the diverse needs of various industries. Sandvik's commitment to sustainability is also commendable, as they strive to develop eco-efficient drilling solutions Sandvik's commitment to sustainability is also commendable, as they strive to develop eco-efficient drilling solutions

This type of grating is commonly used for offshore installations or on ships. It can be safely submerged in water and will not become damaged or corroded by salt water.

A hard rock drill bit is essentially a piece of engineering brilliance, combining robust materials with intricate designs to create a tool that can efficiently fracture and remove hard, abrasive rocks. They are primarily classified into two categories fixed-cutter bits (also known as PDC or Polycrystalline Diamond Compact bits) and roller-cone bits. Each type has its unique advantages and is selected based on the specific drilling conditions and rock types encountered.

...

2025-08-15 01:50

1588

Button bits, in general, are characterized by their compact, dome-shaped cutting heads studded with tungsten carbide buttons. These buttons, when subjected to the 7 degree angle, provide enhanced shearing action, resulting in smoother drilling and longer bit life. The design also allows for better cooling, reducing the risk of overheating and damage to the bit.

...

2025-08-15 01:09

1380

Beyond the physical insertion, the positioning and orientation of the rock bits are equally crucial

...

2025-08-15 01:01

2075

FRP, as the name suggests, is a composite material composed of two primary components fibers and a matrix. The fibers, usually made from glass, carbon, or aramid, provide tensile strength and stiffness, while the plastic resin matrix binds these fibers together, imparting resistance to corrosion and impact. This combination results in a material that is stronger, lighter, and more resilient than traditional materials like steel or concrete.

...

2025-08-15 00:56

2800

Environmental sustainability is another aspect that contributes to the popularity of glass fiber tanks. Their non-toxic properties ensure that they do not leach harmful substances into the stored liquid, making them eco-friendly options for water storage and waste management.

...

2025-08-15 00:23

2209

The mold is the canvas upon which the FRP material is laid like paint, layer by layer. Each layer consists of fiberglass strands or fabric impregnated with a polyester resin. The artisans who perform this task must do so with precision, ensuring each layer is uniformly distributed and free of air bubbles that could compromise the integrity of the final product.

...

2025-08-15 00:14

1466

Grinding: All cut edges should be ground smooth. Use a coarse grit, open coated (resin) grinding disk.

...

2025-08-15 00:11

762

Button bits, in general, are characterized by their compact, dome-shaped cutting heads studded with tungsten carbide buttons. These buttons, when subjected to the 7 degree angle, provide enhanced shearing action, resulting in smoother drilling and longer bit life. The design also allows for better cooling, reducing the risk of overheating and damage to the bit.

Beyond the physical insertion, the positioning and orientation of the rock bits are equally crucial

FRP, as the name suggests, is a composite material composed of two primary components fibers and a matrix. The fibers, usually made from glass, carbon, or aramid, provide tensile strength and stiffness, while the plastic resin matrix binds these fibers together, imparting resistance to corrosion and impact. This combination results in a material that is stronger, lighter, and more resilient than traditional materials like steel or concrete.

Environmental sustainability is another aspect that contributes to the popularity of glass fiber tanks. Their non-toxic properties ensure that they do not leach harmful substances into the stored liquid, making them eco-friendly options for water storage and waste management.

The mold is the canvas upon which the FRP material is laid like paint, layer by layer. Each layer consists of fiberglass strands or fabric impregnated with a polyester resin. The artisans who perform this task must do so with precision, ensuring each layer is uniformly distributed and free of air bubbles that could compromise the integrity of the final product.

Grinding: All cut edges should be ground smooth. Use a coarse grit, open coated (resin) grinding disk.

Their non-conductive properties further enhance safety, reducing the risk of electrical hazards in hazardous environments Their non-conductive properties further enhance safety, reducing the risk of electrical hazards in hazardous environments

Their non-conductive properties further enhance safety, reducing the risk of electrical hazards in hazardous environments Their non-conductive properties further enhance safety, reducing the risk of electrical hazards in hazardous environments frp insulation tank.

frp insulation tank. Sandvik's commitment to sustainability is also commendable, as they strive to develop eco-efficient drilling solutions Sandvik's commitment to sustainability is also commendable, as they strive to develop eco-efficient drilling solutions

Sandvik's commitment to sustainability is also commendable, as they strive to develop eco-efficient drilling solutions Sandvik's commitment to sustainability is also commendable, as they strive to develop eco-efficient drilling solutions Moreover, it provides a sense of privacy while still allowing natural light to filter in, creating a soothing ambiance Moreover, it provides a sense of privacy while still allowing natural light to filter in, creating a soothing ambiance

Moreover, it provides a sense of privacy while still allowing natural light to filter in, creating a soothing ambiance Moreover, it provides a sense of privacy while still allowing natural light to filter in, creating a soothing ambiance

Once installed, they require minimal upkeep, and their robustness ensures long-term durability Once installed, they require minimal upkeep, and their robustness ensures long-term durability

Once installed, they require minimal upkeep, and their robustness ensures long-term durability Once installed, they require minimal upkeep, and their robustness ensures long-term durability

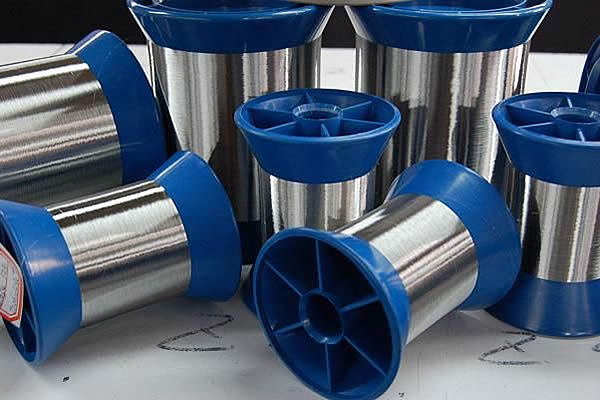

In the medical field, the same wire might be employed for surgical sutures due to its biocompatibility and strength In the medical field, the same wire might be employed for surgical sutures due to its biocompatibility and strength

In the medical field, the same wire might be employed for surgical sutures due to its biocompatibility and strength In the medical field, the same wire might be employed for surgical sutures due to its biocompatibility and strength